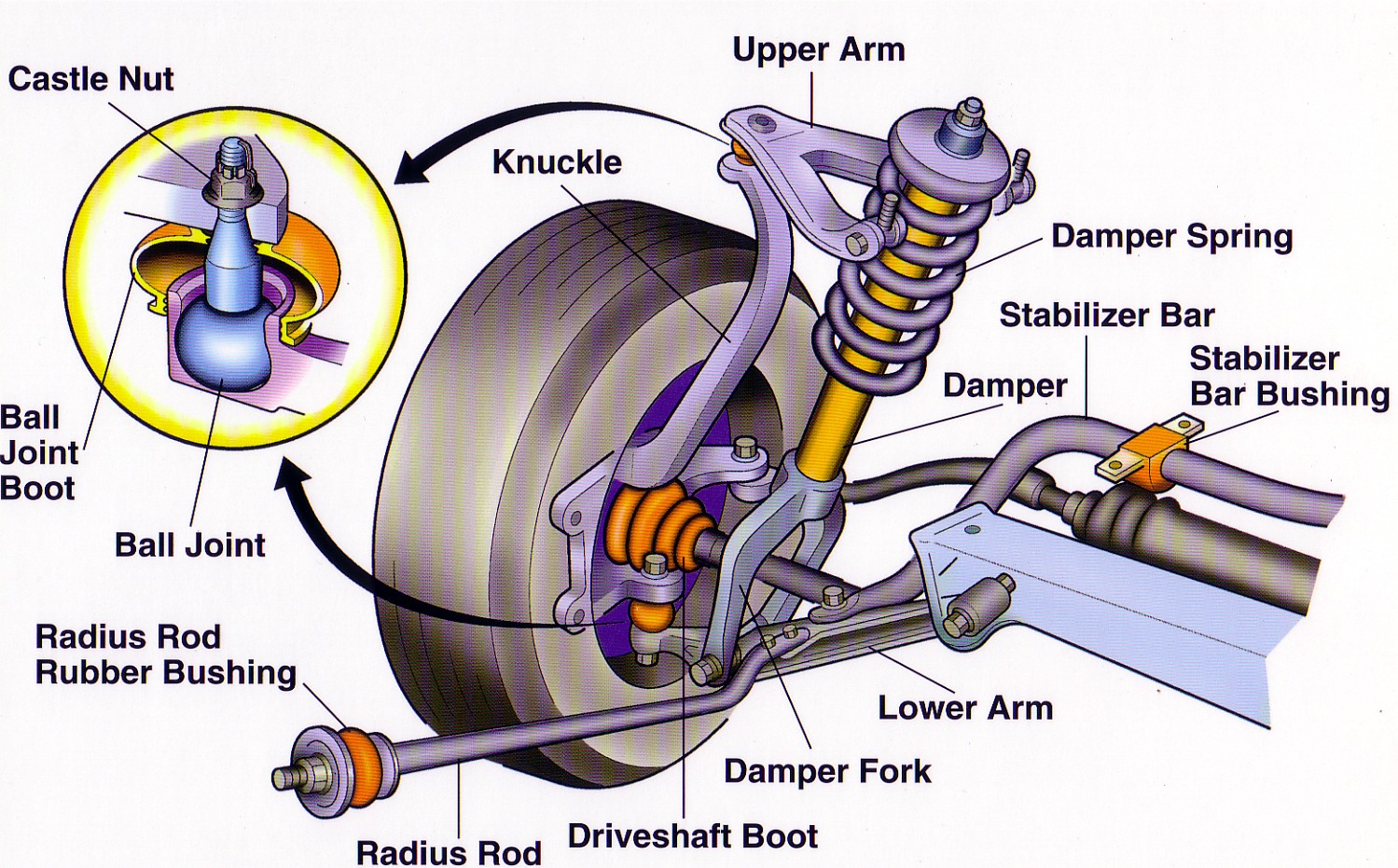

Macpherson strut front end suspension diagram. Wiring diagrams help technicians to view what sort of controls are wired to the system. For more anatomy content please follow us and visit our website:

(a) Conventional passive suspension system, (b

The figure above depicts the layout of an air suspension system.

A diagram of this system is shown below.

We hope this picture car suspension system diagram can help you study and research. Because the most common type of suspension is a macpherson strut, we’re going to focus on the front end parts that are common to that design. The core of suspension system performance is in the details of the development of an integrated suspension system.each suspension system is designed to provide the optimum combination of ride quality and vehicle control.suspension geometry,travel,load capacity, suspension spring rate and damping levels are all. It is basically the structural skeleton which carries the weight and load of the entire vehicle, including its components.

Suspension system | components , types , working principles.

When i safely got home i thought problem was just a stuck dump valve as bags were not filling up when in store/travel mode. Working principle working of independent suspension: Components that make vehicle motion possible by way of grip and/or friction with the road Anatomynote.com found car suspension system diagram from plenty of anatomical pictures on the internet.

Different types of front suspension, besides coil spring type, are also in use.

In this system air springs or air bellows are used: Mechanism that enables the driver to guide and direct the vehicle. Designing an automotive suspension system is an interesting and challenging control problem. Suspension has some different kinds, but there is mcpherson diagram

Each front wheel is supported at the end by a separate i beam.

The diagram noted above has a different air suspension system than the 2005 dynaquest 264sl. This model is for an active suspension system where an actuator is included that is able to generate the control force u to control the motion of the bus body. A diagram of this system is shown below. It is widely used in the front.

Looking directly at the front of the vehicle, camber refers to the tilt in (+) or out (‐) of the bottom half of the tire.

Diagram of an air suspension system: In this system leaf spring or coil spring or both are used. We think this is the most useful anatomy picture that. Here is a picture gallery about front end suspension parts diagram complete with the description of the image, please find the image you need.

The frame is perhaps the biggest component of the suspension system.

2 in this system there is no automatic control device. Air suspension system rigid suspension system; The system protection valve is installed on one of the system air tanks and is used to isolate the brake air supply from every other air system on the vehicle, including the suspension. 5 suspension system terms • camber:

Many people can understand and understand schematics generally known as label or line diagrams.

An air compressor, air accumulator, relief valve, lift control valve, leveling valve, and pipeline are also. This type of diagram is like going for a photograph. The term “macpherson strut” can refer to both a type of strut and the suspension systems that use them. Looking directly at the side of the vehicle, caster refers to the tilt rearward (+) of the bottom half of the tire.

A system of mechanical linkages, springs, dampers that is used to connect the wheels to the chassis is known as a suspension system.

There are many different kinds of front suspension designs in use today. Each type of suspension contains a unique combination of distinct components. The block diagram of the active suspension system is shown in figure 1. Although it helps support the body and engine of the vehicle, there are other components of the suspension system which contribute to this too.

The number of vehicles with air suspension will increase in the next few years, because this system has considerable advantages.

System parameters (m1) 1/4 bus body mass 2500 kg (m2) suspension mass 320 kg (k1) spring constant of suspension system 80,000 n/m The rear suspension was so low i could not crawl under fl to see what was going on. Setup that supports weight, absorbs and dampens shock and helps maintain tire contact. This type of suspension system uses a.

When system air pressure drops to a specific point, usually about 65 to 75 psi, the protection valve closes, isolating the brake system from the suspension and.