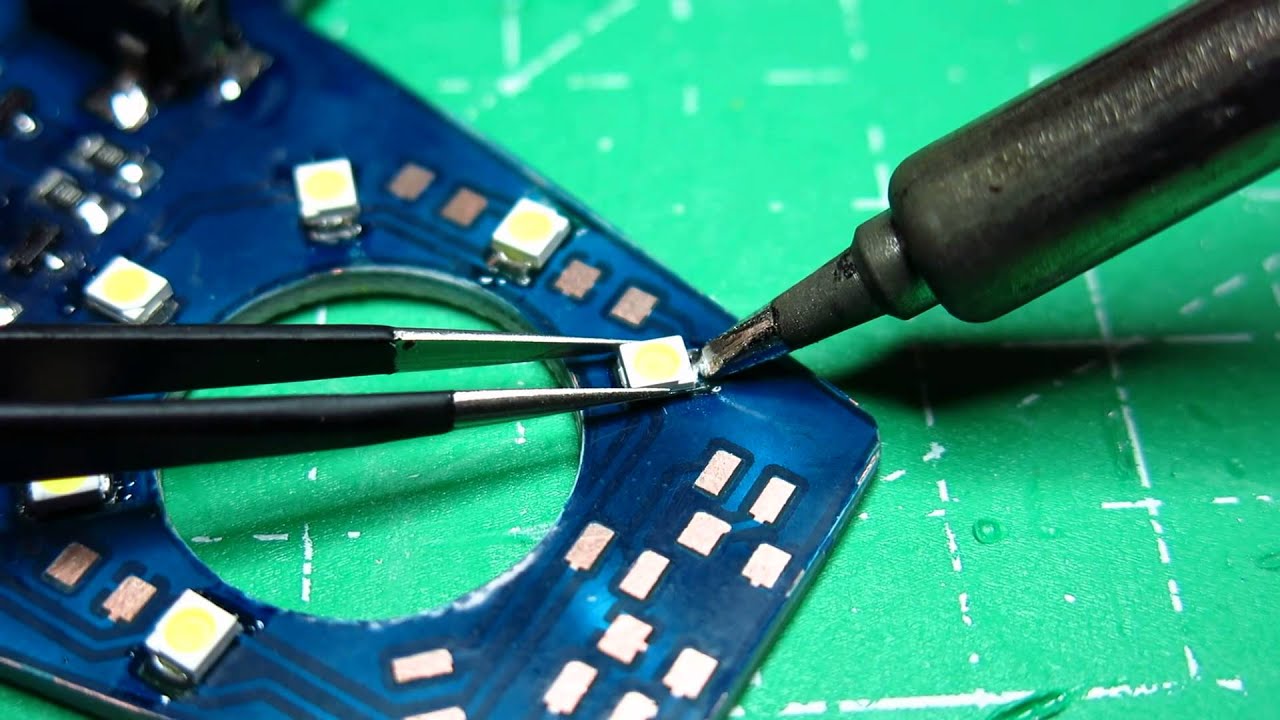

Make sure you have the right tools. Align the desired micro led leg with your resistor and deposit the solder from the iron to the connection. Next, sold the red wire on one strip to the red wire on another using a thin wire or solder.

Soldering SMD LED diodes YouTube

4.4 out of 5 stars.

Double stick foam tape, and regular tape pliers magnifying glass, helpful to be able to see these suckers.

Be sure to hold long enough to not create a cold solder. Any strip that is not cut at. Strip the insulation from one end of each wire. In the first step, you have to cut the led strip to the desired length.

Soldering wire to led strips is easy.

They can be used in a variety of configurations. Twist the stripped ends together and solder them to the strip. Running and brake, running and blinker are examples. Here's what i've needed used:

Temperature controllable iron really helps or if you’re cheap like me, the home depot light dimmer special will work just fine.

Keep this solder dot on the iron. It makes soldering led strip lights so easy even your most inexperienced apprentice will conquer the skill in no time. Place your led strips on the table and use a tape to hold them down so that they don’t move. What are the 3 wires on led lights?

Use a wet sponge to remove excess solder and to keep your tip clean.

An led strip is always marked with segments. I prefer twisting the resistor lead around the led a few times so there’s a mechanical connection in addition to the solder; Melt some solder on the copper dots located on the tips of the led strip lights. A good solder job will allow you to form a robust electrical connection between the strip and your wire.

If you want a stable and working led strip, you need to prepare things like the following beforehand:

To properly tin the tip of an iron apply solder to the tip and coat it thick. Obviously the more clean the surface, the better. Then, after i solder, i trim the excess leads off. When soldering led strip lights, the first step is to remove the clear coating on top of the copper pads.

How do you solder 2 led strips together?

In this video i will be showing you how to solder led strips. For these reasons solderm8 is now fast becoming an essential in every professional electrician’s toolbox. Smd led emitters solder (rosin core) for electrical applications, soldering iron. Choose the right soldering tools recommend using a weller 40 watt soldering iron

Heat up the soldering iron until it smokes a little bit.

Put only a little bit of solder on the tip of the rgb wires and melt it thoroughly. Make sure not to get. Led tape lighting direct soldering of wires is the surest method for making extra reliable electrical connections. Try to avoid holding the soldering iron to the led prong too long or it may burn out the led.

Solder the green wire to the green wire.

Our goal was to use soldering techniques to fuse led lights and sensor wires together with the use of arduino board to make a cool led product. You can connect two sections of strip lights with no soldering. Soldering stations are also useful and readily available online. If you wish to start soldering your led strips, here’s how you can do it:

The next step is to wipe off the excess solder with a wet sponge and finally reapply a little amount of solder to the tip again.

See also 7 best led lights with wall plug. Begin by melting a small portion of solder with your soldering iron. This video will be very useful when customizing your led light strips to your home, car, boat. Once you have tinned both the wire and the copper dots on your rgb led strip light you can now mate the two together.

Solder the resistor to the positive prong.

Individually place the wire to the copper dots and then place the soldering iron over both in order to heat up each solder enough to melt and become one. Soldering two led strips together is easy.