What is extruded polystyrene (xps)? Extruded polystyrene foam, also known as xps foam or the trademarked brand named styrofoam™, is used to make foam products for building materials like insulation to architectural models. Polystyrene is an addition polymer that results when styrene monomers interconnect (polymerization).

extruded polystyrene foam Manufacturer in Malaysia by

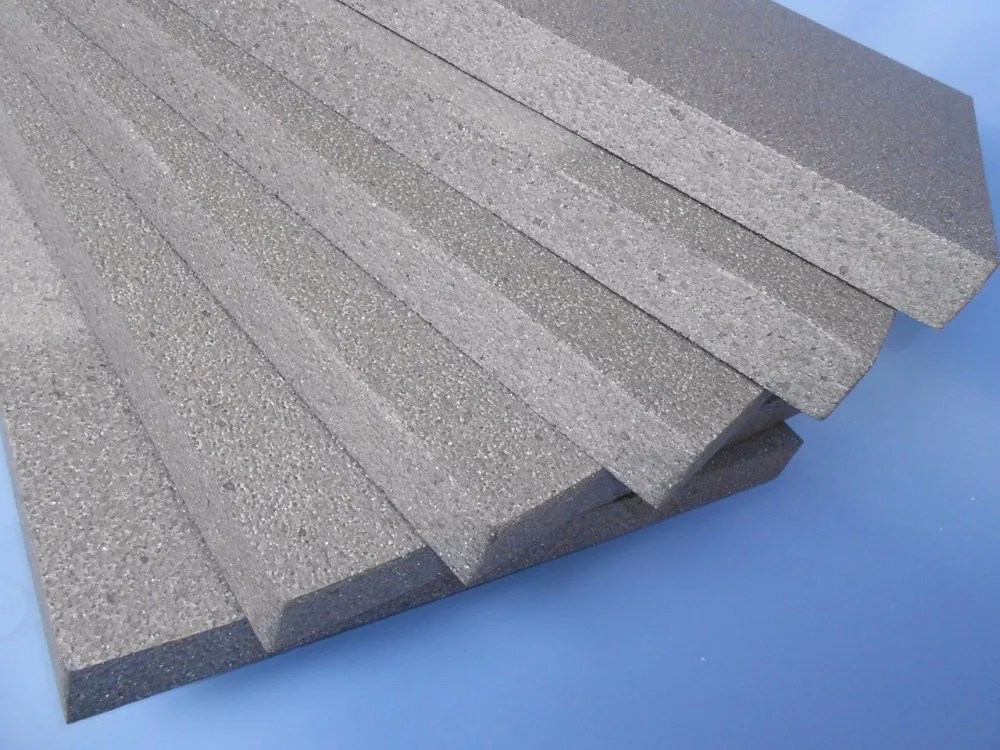

Continuous extrusion produces a tight and complete skin (free of open cells) to form on each side of the insulation board.

Polystyrene foam is known for its outstanding thermal insulation.

Each manufacturer has a unique color to differentiate their product. Extruded polystyrene rigid foams has a high resistance to water absorption and mechanical properties. Polystyrene foam products come in two different forms. The manufacturing process combined with the intrinsic qualities of the static componetent thermo plastic material gives extruded polystyrene predictable long term performance and high insulating value.

Technonicol company specialists have developed a unique technology for producing extruded polystyrene slabs with nanoscale carbon particles.

2.70 g/cm 3 for aluminium). This material is light blue in color and is owned and manufactured by dupont.dupont also has produced a line of green and. What is extruded polystyrene used for? In practice, this is one of the best indicators in the construction industry for widely used heat insulators.

In addition to styrene monomer, ethylene and benzene are also present in the xps.

Xps boards are extruded to a specific thickness during This is the strongest, trump material parameter: You can choose between extruded polystyrene (xps) or expanded polystyrene (eps), each used for specific and different applications. Expanded polystyrene is a type of foam made from polystyrene.

It is a lightweight, rigid and closed cell insulation.

A solid polystyrene is also used to manufacture expanded polystyrene (eps). Polystyrene is a synthetic, hydrocarbon polymer derived from benzene and ethylene, two petroleum products. This synthetic polymer is fragrant and is made of styrene monomer. Extruded polystyrene is about as strong as an unalloyed aluminium but much more flexible and much less dense (1.05 g/cm 3 for polystyrene vs.

Closed cells are integrally formed within the insulation materials during the expansion process.

Extruded polystyrene, often referred to as xps, is manufactured by four different companies in the united states. Extruded polystyrene (xps) is one of the most efficient thermal insulation materials, which is widely used in the construction of foundations, basements, floors, walls, roofs, pipelines, roads and railways. The key difference between expanded and extruded polystyrene is that we produce expanded polystyrene (or eps) from solid beads of polystyrene while we produce extruded polystyrene (or xps) from solid polystyrene crystals. Extruded polystyrene is a type of polystyrene that is stronger than hips.

Generally, polystyrene is a synthetic aromatic polymer made from the monomer styrene, which is derived from benzene and ethylene, both petroleum products.polystyrene can be solid or foamed.polystyrene is a colorless, transparent thermoplastic, which is commonly used to make foam board or beadboard insulation and a.

Extruded polystyrene (xps) insulation is created through an extrusion process, where hfc blowing agents, colorants and other additives are melted together to form a liquid. Other cfcs and hcfcs have odps that range from 0.01 to 1.0. Pipe and equipment passive fire protection appliances industrial insulation homepage. The manufacturers have production facilities in different parts of the country, producing similar products.

Choose from our selection of extruded polystyrene, including over 80 products in a wide range of styles and sizes.

It is interesting to note that xps is more expensive than eps. Extruded polystyrene board is formed from a polystyrene polymer. Thermal conductivity at 25±5°c, not more than 0.032 w / (m*k). Extruded polystyrene does not require additional waterproofing, and hence the cost of it.

Xps foam board is a rigid thermoplastic material manufactured from polystyrene.

Extruded polystyrene is a type of plastic used to make products ranging from building materials to storage containers.this product may also be referred to as xps, and is also referred to as styrofoam® after a popular brand name version of this material. Odp a number that refers to the amount of ozone depletion caused by a substance. All four manufacturers produce a 25 psi, 40 psi and 60. We provide a full range of capabilities to complete your xps demands, so you never have to worry.

That liquid is extruded through a die, and when cooled, it forms a rigid insulation panel.