How to size a flex duct. Flex duct cfm will measure less than the airflow in sheet metal and for coated fiberglass duct board. For instance a 2.5 ton system (approximately 400 cfm per ton) would require (2) 14” flexible return ducts or (1) very short flexible 18” duct to.

FIELD DUCT SIZINGCHARTs by Navid Anari Issuu

For instance, if the diffuser neck size is 150mm (6″), the flexible duct size is also 150mm (6″) and therefore, the duct height needs to be 200mm (8″) in order to fit the flexible duct.

Multiply the length and width together to get the.

16 up to 11” 40’ el 12” to 15” 55’ el 16” to 21” 75’ el 22” to 27” 100’ el 28” to 33” 125’ el return air. Most technicians are skeptical about these numbers, especially on the return air side of the system. 14 up to 11” 10’ el 12” to 21” 15’ el 22” to 27” 20’ el 28” to 33” 25’ el duct elbows, square throat no. Read friction loss (inches of water) and duct velocity (fpm).

Flex duct cfm changes based on how it’s installed,.

Sizing ducts, the attached chart can be used in most single story homes with a centrally located unit, and reasonable length duct runs. Insulated flexible duct r8 silver jacket is used in standard heating and air conditioning (hvac) systems and some venting applications. At that point the flex duct is clamped down. • the chart is based on metal duct.

Enter the desired length of the rectangular duct.

Duct elbows, radius throat no. Enter round duct diameter (inches), duct airflow (cfm), duct length and the number of bends. • the chart should not be used to design complete duct systems. • ashrae 2012 hvac systems and equipment, box plenum systems using flexible duct.

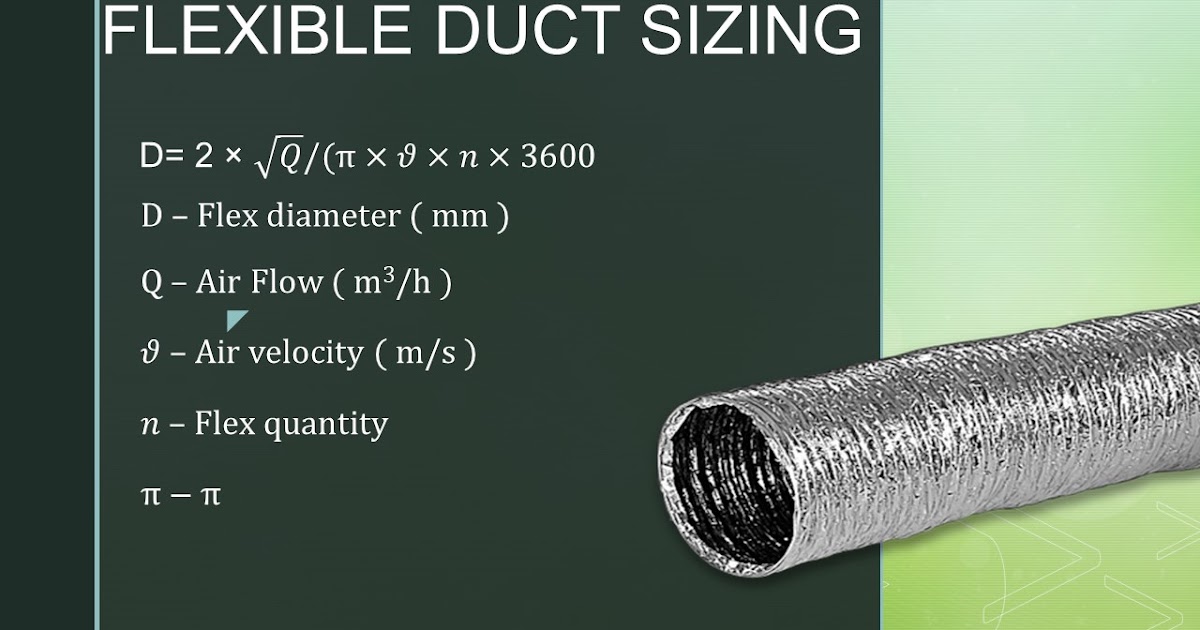

Keep in mind, duct material choice also affects airflow resistance and static pressure, therefore calculations for flexible duct sizing differ slightly from sheet metal ductwork.

Easy to use online ductulator / duct size calculator, metric or english units. Flex duct =.05 on most metal duct calculator round metal pipe =.06 on most metal duct. Read duct diameter (inches) and duct velocity (fpm). Flexible ductwork can be sized using a ductulator or a friction loss chart.

Flex duct, ductboard, or metal duct options.

Flex duct =.05 on most metal duct calculator round metal pipe =.06 on most metal duct. This brand of flexible ductwork specifies that it should be sized at a pressure loss of 0.8 pa/m. The duct size calculator is a quick reference tool for approximating duct sizes and equivalent. The specific measurement will depend on the type of hose in question, but id measurements in flex duct sizing typically range from 1” to 24”.

Basically, you need the duct to be tall enough to open a duct collar for a flexible duct connection.

All flexible ducting hoses have an id size. • to insure proper distribution of air, volume dampers must be used for all branch runs. Insulated flexible duct r8 silver jacket the master flow 6 in. • cfm = fpm x area given any two of these three quantities, the third can be readily determined:

Rigid sheet metal provides the least airflow resistance.

The inside diameter of flex hose is important because, this size fits over the od of the pipe that it is connected to. Insulated the master flow 6 in. For 15% longitudinal compression the friction rate can increase by a factor of two (15% = 2 x friction rate). The duct has r8 insulation which contains 50% more insulation than the standard r4.2 product.

Flex duct has a higher pressure drop and as such may require the size shown on this guide be increased by 1 round size for up to 800 cfm and 2 round sizes

Measure the length and width of the room where the flex duct will be supplying the air.