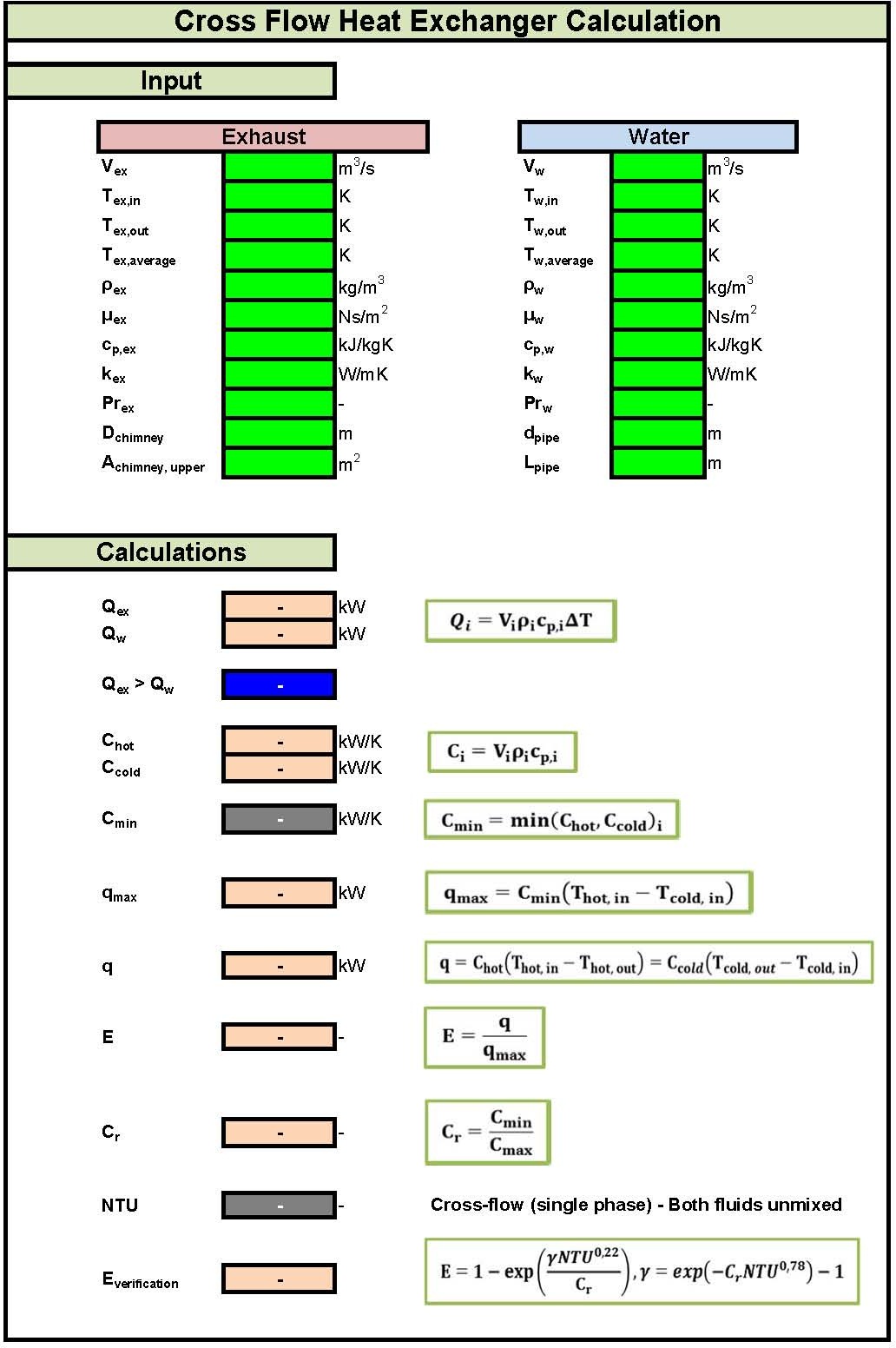

The plate heat exchangers are further divided into cross and counterflow exchangers due to their different airflow configurations. There are two categories of air to air heat exchangers, rotary and plate heat exchangers. It is expressed as a ratio.

Figure A17 Heat exchanger calculations in Excel

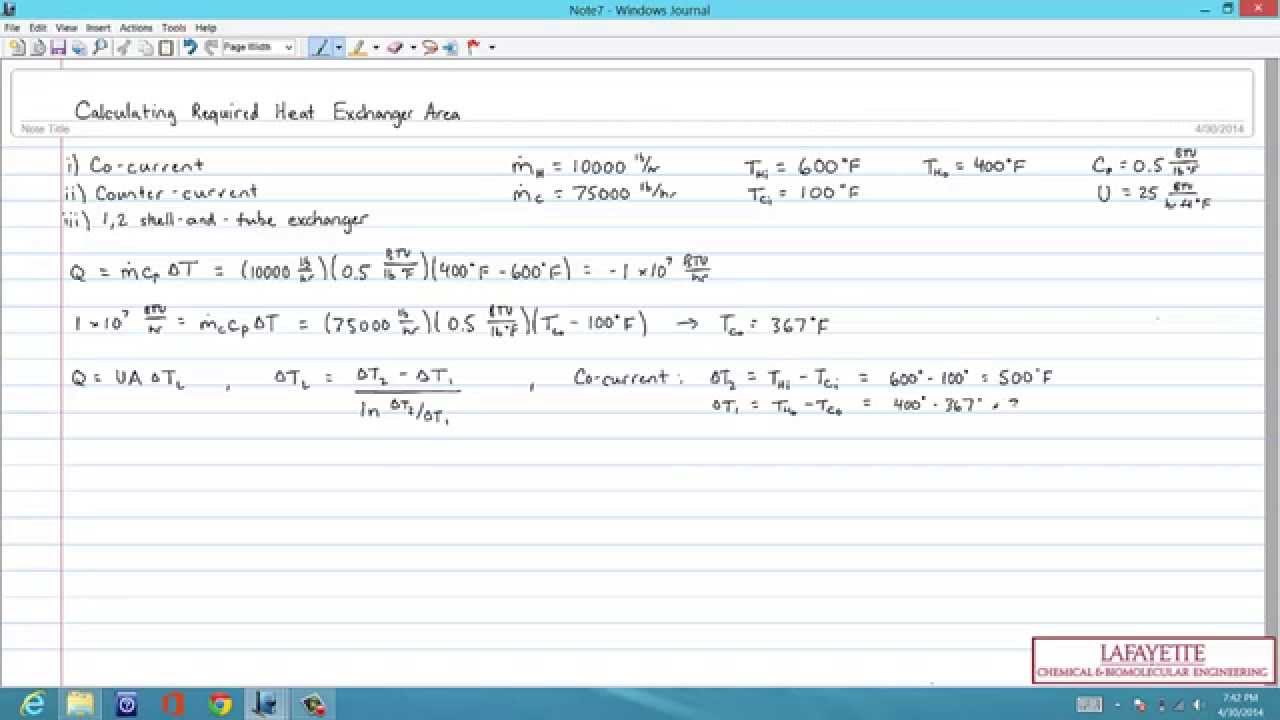

Then the basic design equation becomes:

The heat load of a heat exchanger can be derived from the following two formulas:

Plate heat exchangers are efficient heat recovery units used in a range of commercial, industrial, and residential settings. Manufacturing in the czech republic for 10 years, we now have the widest range in the market. When the overall heat transfer coefficient is constant and the other assumptions of the mean temperature difference concept apply. E = q / qmax.

The approximating 𝑖(𝜗𝑖) 1can be expressed as:

In practice, all the thermal duty of the hot fluid (fc) is transferred to the cold fluid (ff), thereby fulfilling the next energy balance: Definition of the process for the calculation of heat exchangers. For more information, please visit the products page. By extracting sensible energy from exhaust air, and using it to cool or heat incoming air, a plate heat exchanger can make a dramatic difference to a building’s energy costs and environmental impact.

Calculate heat exchanger surface area:

Figure 1 shows that the values of approximating 𝑖(𝜗𝑖) are closed to the real ones. Enter the fluid flow rate, temperature and pressure at the heat exchanger inlets. Heat transfer air cooled heat exchanger this web application does preliminary estimation of finned area, face area, total fan power, air outlet temperature for an air cooler. The overall heat transfer coefficient, u, and the log mean temperature difference for the heat exchanger, δtlm, based on.

Our dpl is an all welded plate type heat exchanger with the.

• the deviations of model predictions to the experimental data are within 10%. 8 with the dimensionless capacity rate ratio max min c c z & & = eq. We produce quality counterflow heat exchangers for recovery units. Under project information select either ip for ºf or si for ºc.

Plate heat exchangers are efficient heat recovery units used in a range of commercial, industrial and residential settings.

A nominal value of 25℃ is selected for 𝜗𝑖,0. How to use the ael plate heat exchanger sizing calculator all that you need to do is to click on this link and “go to the filter index” on the left hand side of the page and select the type of installation you are working on. • it can calculate both heat transfer and flow resistance. The thermal duty of a fluid in liquid state depends on the mass flowrate and.

The dpl utilizes dimples on each plate to maintain plate spacing and enhance turbulence while operating at lower pressure drop.

Once you have selected the type of installation you are working on you then “choose the type of heat exchanger” you would prefer. Select a tube side (product) fluid and shell side (working) fluid. By extracting sensible energy from exhaust air, and using it to cool or heat incoming air, a plate heat exchanger can make a dramatic difference to a building’s energy costs and environmental impact. The efficiency is improved by its slim profiles and our latest patented plate design, creating high turbulence even at lower velocities while.

• it is capable of predicting performance with only nominal data.

The heat transfer area can be calculated after values have been determined or estimated for the required heat transfer rate, q; Model h2 is our most efficient cross flow plate heat exchanger. 1/k = 1/α 1 + δ ст /λ ст + 1/α 2 + r заг. A heat exchanger is an energy exchange system (in the form of heat) between a hot and a cold fluid.

P = heat load (btu/h) m = mass flow rate (lb/h) c p = specific heat (btu/lb °f) δt = temperature difference between inlet and outlet on one side (°f) k = heat transfer coefficient (btu/ft 2 h °f)

Μt = temperature transfer efficiency. • it does not need geometric data as inputs or require numerical discretization. In the rate mode, the calculator will provide the output temperatures of the air streams based on the input conditions. This approach is most common when building managers or engineers are attempting to determine the heat transfer rate and the fluid exit temperatures, and already know the size of the heat exchanger and the inlet temperatures.

Heat load, theta and lmtd calculation.

Qt =u * a*f(lmtd) (2.1) where qt is the total heat load to be transferred, u* is the overall heat transfer coefficient referred to the area a*, a* is any convenient heat transfer area, lmtd is the.